The home building industry is facing some rough seas. Labor shortages and supply chain disruptions are rocking the boat, messing with project timelines and profits. The industry lost a ton of construction jobs during the pandemic – over a million, in fact. Things have picked up, but the homebuilding industry was still short almost half a million workers at the end of 2023. And it’s not just finding people; getting materials is a headache too. Construction costs have jumped by almost 40% since 2020, and supplies take forever to show up on site. It used to take under 7 months to build a typical house, but now it’s over 8 – all thanks to these problems.

This isn’t just a temporary storm; it’s a whole new weather pattern for home builders. Builders might want to adjust their sails if they want to stay afloat. In this post, we’ll dive into what’s causing these issues, how they’re affecting the industry, and what can be done about it. Plus, we’ll look at how Outhouse can help builders work smarter, not harder.

Where Have All the Workers Gone?

The labor shortage is a big problem with deep roots. One reason is the “silver tsunami” – experienced workers are retiring, and not enough young folks are stepping up to take their place. For every five retirees, the home building industry only gets about two new workers. That gap is getting wider and wider, leaving home building high and dry, especially for skilled trades. Across the U.S., the construction industry has about 8.3 million construction workers, with 3.4 million in home building, but it’s not enough. A whopping 65% of builders can’t find enough finish carpenters. This drives up labor costs and throws off schedules. To put it in perspective, the industry needed over half a million extra workers in 2024 just to keep up. This is even worse than the shortage during the housing boom back in the mid-2000s, even though fewer homes are being built now. Something has to give!

So, why aren’t young people interested in construction?

- College Craze: Many young people think a college degree is the only ticket to success, so they’re not going to trade schools.

- Tough Job: Construction can be tough on the body and sometimes dangerous, which doesn’t appeal to everyone.

- Competition: Other industries like manufacturing are also scrambling for workers, so everyone isl fighting over the same talent pool.

Supply Chain Snags

The pandemic really showed the world how fragile our supply chains are. Closed borders, factories shutting down, and transportation issues created a real mess, making it hard to get materials and driving up prices. It didn’t help that everyone started panic-buying, which made things even worse .

Lumber prices went through the roof. Appliances, windows, and doors were like gold dust. Projects got delayed, and costs went up all around.

Even though the pandemic is mostly behind us, the supply chain is still tangled. The war in Ukraine, high energy costs, and ongoing shipping problems are keeping things unpredictable. Some companies are turning to tech to help, using things like “control towers” to track materials and adjust to changes quickly.

Strategies for Success

Builders should consider being proactive to navigate these challenges. Here are some strategies that can help:

Finding and Keeping Skilled Workers

- Invest in the Future: Builders can create apprenticeship programs and on-the-job training to bring in new talent and keep our current workers sharp. Some industry groups like the Home Builders Institute (HBI) and Lowe’s Foundation are putting money into training programs to get more people into the trades. Programs like The House That She Built work to educate young people about the opportunities available in the building industry.

- Cast a Wider Net: Look beyond the usual places to find workers. Reach out to women, veterans, and people who were formerly incarcerated. Partnering with community groups and schools can help us connect with potential employees.

- Show Appreciation: To keep good workers, consider offering competitive pay, offer great benefits, and give them chances to grow. Think health insurance, retirement plans, paid time off, and opportunities for promotions.

- Embrace Technology: Technology can help do more with fewer people. This includes things like automation, prefabrication, and digital tools for managing projects . By investing in technology, home builders can make jobs more efficient and appealing.

Getting Needed Materials

- Team Up with Suppliers: Strong relationships with suppliers are key to getting needed materials on time. Open communication and working together can help everyone in the supply chain anticipate problems and find solutions.

- Don’t Put All Your Eggs in One Basket: Have backup plans. Find new suppliers and consider using different materials if current suppliers run into shortages or hike up prices.

- Plan Ahead: Ordering materials in advance and keeping enough on hand can help avoid delays and price swings.

Working Smarter, Not Harder

- Simplify Choices: One way to ease the strain on the supply chain is to offer fewer product choices, sticking with materials that are readily available .

- Package Deals: Offering pre-selected material packages can make things easier for everyone and ensure that everything works together.

- Order Early: For important things like windows ordering them six months ahead of time and storing them can prevent delays. This takes some planning and space, but it can be worth it.

- Speak Up: Advocate for policies that can help fix supply chain problems. This includes supporting efforts to increase production of things like electrical transformers.

How Outhouse Can Help

Outhouse.net has some great tools that can help home builders work more efficiently and deal with labor and supply chain issues. By outsourcing your drafting to Outhouse, you can save money and get top-notch expertise .

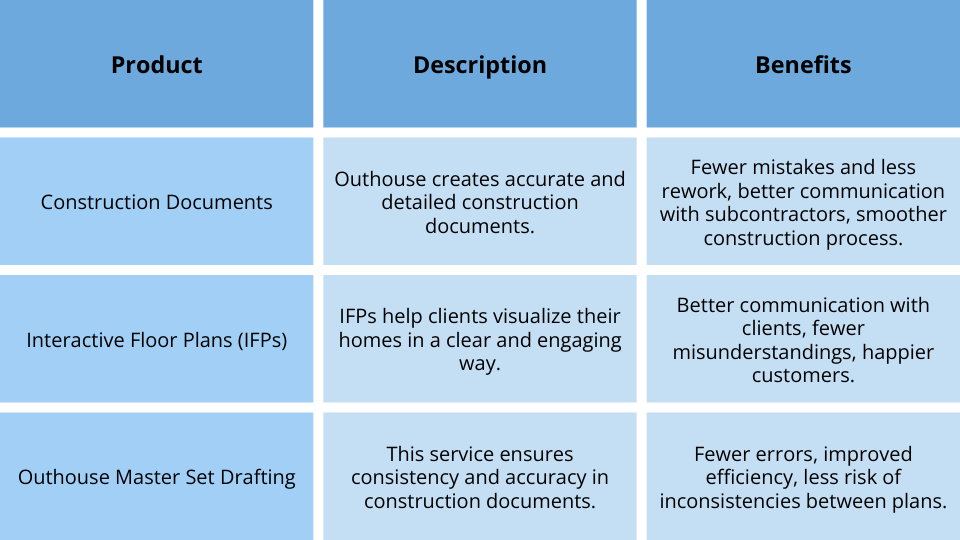

Here’s a quick look at what we offer:

Here’s how these tools can help:

- Less Rework: Accurate plans mean fewer errors and less time and money wasted on fixing mistakes.

- Clearer Communication: IFPs and other visual tools help everyone understand the plan, preventing confusion and delays.

- Smoother Operations: Outhouse products help streamline the design and construction process, making things more efficient.

Riding the Wave

The labor shortage and supply chain disruptions are tough challenges, but home builders can overcome them. By investing in the workforce, building strong relationships with suppliers, using technology wisely, and taking advantage of tools like those offered by Outhouse, home builders can weather this storm and continue building quality homes efficiently and profitably.